The Dumpmaster safely empties any kind of bin at any height, with a unique electro-hydraulic mechanism that can lift and tip more than 250kg. The Dumpmaster is the safest, fastest and most reliable bin tipper on the market, and has been continuously improved over more than thirty years.

Dumpmaster bin tippers are very versatile and are used in dozens of applications; from emptying rubbish bins into skips to pouring food ingredients into mixers. They feature a unique tipping action which lifts the bin straight up, then gently rolls it upside down over the lip of the receptacle. Less than 1m3 of floor space is required regardless of tipping height, since the weight of the bin is maintained within the floor footprint at all times.

The Dumpmaster was designed for safety, with full guarding and door interlock systems fitted as standard. The machine can be optionally certified to various standards, including ISO 12100, AS/NZS 4024, and CE.

No matter how it is used, the Simpro Dumpmaster has proven to be safe, reliable and economical to operate, year after year.

Download_Dumper HD Electrioc Bin Lifter (PDF)Dumpmaster Features:

Dumpmaster Videos:

Dumpmaster Options and Accessories

[/su_column] [su_column size=”1/3″]

[/su_column] [/su_row]

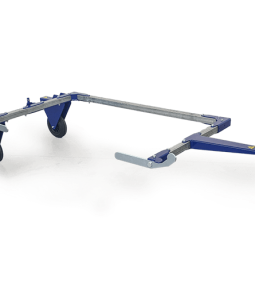

Unlike a regular Dumpmaster, the Dockmaster is designed to invert bins as low as possible, at just 700mm. To allow operating near platform edges a pair of safety rails are fitted adjacent to the castor wheels, which catch the machine if it is rolled off the edge – instantly preventing further movement.

[/su_column]

[su_column size=”1/3″]

[/su_column]

[/su_row]

[/su_column] [su_column size=”1/3″]

[/su_column] [/su_row]

Construction from 316-grade steel is also available.

[/su_column] [su_column size=”1/3″]

[/su_column] [/su_row]

[/su_column] [su_column size=”1/3″]

[/su_column] [/su_row]

[/su_column] [su_column size=”1/3″]

[/su_column] [/su_row]

Unlike a regular Dumpmaster, the Dockmaster is designed to invert bins as low as possible, at just 700mm. To allow operating near platform edges a pair of safety rails are fitted adjacent to the castor wheels, which catch the machine if it is rolled off the edge – instantly preventing further movement.

[/su_column]

[su_column size=”1/3″]

[/su_column]

[/su_row]

All types of door are now fitted with a solenoid operated lock. This means that while the bin is off the ground, the door is locked. The door can only be unlocked once the cradle is back on the ground, and once the do the door or is opened the machine cannot run.

[/su_column]

[su_column size=”1/3″]

[/su_column]

[/su_row]

[/su_column] [su_column size=”1/3″]

[/su_column] [/su_row]

[/su_column] [su_column size=”1/3″]

[/su_column] [/su_row]

PET-G standards for Polyethylene Terephthalate Glycol-modified, which is a virtually unbreakable, transparent plastic material.

PET-G can be more difficult to keep looking clean than wire mesh.

[/su_column]

[su_column size=”1/3″]

[/su_column]

[/su_row]

Foot guard panels are available for most Dumpmaster models to prevent the operator’s feet from going under the machine frame. The guards bolt between the frame and castors, and are very easily fitted.

An auto-cycle controller is available for mains-powered machines only. This unit connects directly into a standard wiring loom, and has 3 potentiometers to adjust the raise, hold, and lower times.

For more complex functions (e.g. interacting with other equipment) a programmable relay is available.

This equipment does requires that the cradle sit slightly off the ground, and a ramp is provided with the scale kit.

[/su_column]

[su_column size=”1/3″]

[/su_column]

[/su_row]

Dumpmaster Specifications:

| Model | DM0700* | DM1200 | DM1500 | DM1800 | DM2100 | DM-CUSTOM |

|---|---|---|---|---|---|---|

| Tipping height (“TH”) | 700mm | 1200mm | 1500mm | 1800mm | 2100mm | xxxx mm |

| Height (“OH”) | 1770mm | 2260mm | 2560mm | 2860mm | 3160mm | xxxx + 1060mm |

| Guarding height (“GH”) | 1755mm | 2200mm | ||||

| Width | 964mm | |||||

| Length (door closed / open) | 1170mm / 1834mm | |||||

| Weight | ~160kg | ~205kg | ~215kg | ~225kg | ~235kg | xxxx / 30 + 165kg |

| Capacity (max bin weight) | 250kg | |||||

| Bin compatibility (standard cradle) | 60L, 80L, 120L, 140L, 240L EN840 wheelie bins (options: custom cradle) | |||||

| Bin throw (“BT”) | ~100mm (with 240L wheelie bin) | |||||

| Electrical specifications (battery power) | Onboard digital float charger (input: 85-264VAC 47-63hz, max draw 3 Amps), with 2x 12V 21Ah deep-cycle sealed gel batteries in series configuration, 0.8kW DC electric motor, and 24VDC control circuit (options: solar panel) | |||||

| Electrical specifications (1-phase power) | 1-phase mains supply (120/240VAC 50-60hz, max draw 8 Amps), with Variable Speed Drive (VSD) controller driving 0.75kW AC electric motor, and 24VDC control circuit | |||||

| Electrical specifications (3-phase power) | 3-phase mains supply (380-415VAC 50-60hz, max draw 1.9 Amps), with 0.75kW AC electric motor, and 24VDC control circuit | |||||

| User interface | Raise/Lower buttons, key switch, battery indicator, master lockout switch (options: VSD joystick, autocycle unit with Emergency Stop button) | |||||

| Ingress protection | IP55 (options: IP56, IP66, IP69K) | |||||

| Cradle travel speed (lifting / lowering) | 0.4m/s / 0.28m/s | |||||

| Tipping cycle duration | ~8s | ~11s | ~13s | ~15s | ~17s | xxxx / 166 + 4s |

| Sound level at operator’s ear | ≤ 60dB | |||||

| Materials | Hot-dip galvanised mild steel frame, galvanised mild steel cradle, 25x25x2.5mm zinc-plated wire mesh guarding (options: sheet metal guarding, polycarbonate guarding, full or partial 304 or 316 stainless steel) | |||||

| Door | Left-hinged door with solenoid-operated electrical safety interlock (options: right-hinged door, swing-up door, roller door) | |||||

| Wheels | ⌀100mm Blue Resilex castors (options: ⌀200mm castors, bolt-down lugs) | |||||

| Applicable Standards and Certifications | AS/NZS4024, ISO 13849-1, IEC 62061, Conformité Européene (CE), EN 349 1993, EN 574 1996+A1:200, EN 953 1997, EN ISO 4413 2010, EN ISO 12100 2010, EN ISO13849-1 2006, EN ISO 13857 2008, EN 60204 2006+A1 2009, EN61000-6-2 2005, EN61000-6-4 2007, Machinery Directive 2006/42/EC, Electromagnetic Compatibility Directive 2004/108/EC | |||||

*The DM0700 model is normally specified as the Dockmaster variant, optimised for emptying bins from elevated loading docks and platforms.

Dumpmaster Dimensions: